Due to the increase in energy demand, the most frequently used energy sources have begun to shrink and may become insufficient in the next few years. Deposits are depleting, so it is necessary to search for them in more and more distant and less depleted places, e.g. in the Arctic. All this makes the production of electricity and heat more expensive, and thus end users – consumers are forced to bear much higher costs. Additionally, and perhaps most importantly, obtaining electricity and heat from fossil fuels such as oil and coal has negative and irreversible environmental effects.

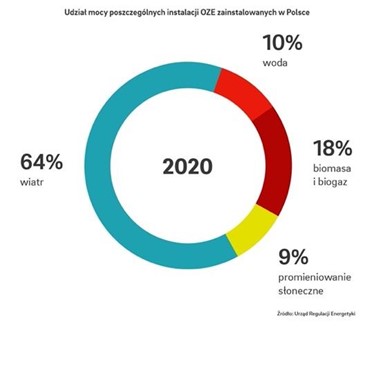

The need to search for inexhaustible, ecological energy sources seems obvious and for some time the majority of this type of investment has definitely been dominating. When it comes to new production capacities around the world – in 2020, renewable energy sources accounted for approx. 80% of all initiatives of this type. This means that the share of renewable energy sources in the global energy production increased to 50% at the end of 2020. In Poland, the most renewable energy is generated by installations which use wind energy, biomass and biogas combustion. Solar energy, despite its growing popularity, is only in 4th place, right after hydroelectric power plants.

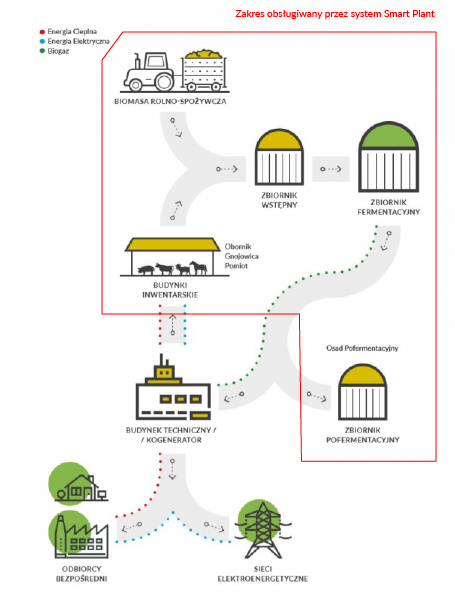

In Poland, the second most popular method of producing energy from renewable sources is the processing of biomass. One of the more interesting ways of using it is the ecological and safe processing of bio-waste into gas, which is used as fuel for the production of electricity and heat. This process is entirely carried out in biogas plants, and the biogas production technology has been available on the market and has been popularized for over 20 years.

Biogas plant – a big stomach

Biogas is produced as a result of anaerobic methane fermentation, and the substrate used for its production is biomass from agri-food processing and farming, including silage from energy crops (e.g. corn, grasses, rye), waste from agri-food processing (e.g. beet pulp, fruit and vegetable pomace), slurry, manure, animal waste, etc.

The key to efficient and safe biogas production is the proper management of the production process.

To make it easier to understand, let’s try to imagine a biogas plant as a large stomach, into which various organic substrates (waste) go, and our task is to create an optimal diet and manage the digestive process. Each of the substrates has different properties and a different potential to generate biogas, and some of them react very strongly when combined. A properly composed diet for such a stomach is therefore of key importance. The selection of the right amount of individual ingredients and their mutual composition determines the amount of biogas produced, as well as the course of the entire digestion process (fermentation) – whether it will be calm and gentle or turbulent and we will experience ‘gastric problems.’

In the case of a single stomach (a single biogas plant), it is easy to imagine that most of the processes – although very labor-intensive – are carried out manually. The challenge begins with a biogas farm where one esophagus has to fill several stomachs. Then there is a need to manage an extensive logistic process involving supply and simultaneous operation of several fermentation processes.

However, apart from ensuring the continuity of the supply of substrates, it is also very important to monitor their quality on an ongoing basis and anticipate interactions between individual nutrients. Constant supervision through dedicated system equipped with predictive tools would be a huge support. It would significantly increase production efficiency and reduce the risks of uncontrolled reactions inside the fermentation tanks as a result of wrong choice of substrates, wrong quantity or simple human error.

For manufacturers who face the above-mentioned challenges, it is a key moment to consider changing their strategy and analyzing the legitimacy of a decision to invest in new technological solutions.

Such a decision requires a cold assessment of the profit from such an investment and the possibility of finding a reliable partner with the appropriate experience, knowledge and potential to implement the necessary software as well as adjust devices and process parameters configuration.

Intelligent biogas plant

The Smart Plant solution is a very interesting project that can become an inspiration when choosing this type of advanced tools. Its task is to optimize the work of biogas plants with the use of created for such purpose machine learning algorithms, connected with appropriate actuating devices.

In addition to activities aimed at adapting the machine park to the acceptance and processing of diverse biomass material, as part of the project, dedicated software was implemented for the control and management of the biogas production process, supply chain economy and prediction of the level of electricity production. The entire solution was built using AI technology with the ability to remotely monitor and manage principal processes.

The implemented technology allows to fully use the potential of the biogas plant, increase its efficiency and significantly reduce the cost of utilization of the available biomass resources. In addition, it reduces the costs of maintenance and service by introducing the process of automating the selection of the type of substrates and their quantity. This will directly translate into the reduction of the necessary personnel and, to a large extent, reduction of problems caused by improper dosing of biomass components.

The machine learning algorithm used in the control software allows to optimize the biogas production process, ensuring its stability even when using substrates of different quality. The designed solution has an internal prediction module, production planning module, reporting and operating module.

The solution was implemented in one of the largest Groups in Poland that produce electricity from biogas. As assured by the Group’s management, each newly built biogas plant will be equipped with the Smart Plant management system.

If you are wondering how to improve the functioning of your biogas plant or you need support in preparing a solution for the automation of production processes – please contact us. The project described above is one of the several systems we implement for the industrial sector. We also invite you to consult us, we are happy to share our knowledge and experience.